Why a Triple Air Filtration System Is Essential for Safe Home 3D Printing

You want a capable printer at home without worrying about fumes or lingering smells. The main risks are invisible: ultrafine particles and VOCs released during extrusion, especially on long jobs or when printing ABS and PC. The safest path is simple. Use an enclosed machine, filter the chamber air effectively, and set up your space so the air you breathe stays clean.

Safety Notice: This article provides general guidance on 3D printer air quality and filtration systems. Individual safety requirements may vary based on local regulations, room conditions, and personal health factors. Pregnant women, children, individuals with respiratory conditions, or those sensitive to chemical exposure should consult healthcare professionals before operating 3D printing equipment in shared spaces.

How QIDI Q2's Triple Filtration Keeps Indoor Air Cleaner

Home printing releases airborne particles and gases around the hot end and part. The goal is to contain them inside the build chamber and treat the air before it reenters the room. The Q2 approaches this with a sealed path and a three-stage filter that addresses different pollutant types. This is where a 3D printer earns its place in shared living areas.

What Each Stage Targets

- G3 pre-filter captures visible dust and debris, so the main media lasts longer. This coarse stage mainly traps larger particles such as lint, hair, and household dust, helping protect the HEPA and carbon layers.

- H12 HEPA captures 99.5% of fine particulates (tested per EN 1822 standard for 0.3-micron particles, the most penetrating particle size), focusing on removing ultrafine matter from the airstream that poses the greatest health risk.

- Activated carbon adsorbs common printing VOCs and reduces material odor, which helps when working with ABS, PC, or nylon. Carbon media effectiveness varies by compound; replacement intervals should reflect actual material usage.

Airflow That Suits Small Rooms

A closed chamber guides air through the filter stack rather than letting warm air drift into the space. Conditioning the chamber air during the print and for a short period afterward lowers what escapes when you open the door to collect parts.

Care That Keeps Performance Steady

Check the pre-filter for lint buildup and clean or replace it when airflow drops. Replace the HEPA and carbon media on a schedule that reflects hours of use and material choice. Keep the door closed for a few minutes after completion so the filter keeps scrubbing internal air while the chamber cools.

Do MET and IECEE CB Certifications Really Improve Safety?

Safety marks matter when a printer may run for many hours near family, pets, or students. The Q2 carries a MET mark, issued by an OSHA-recognized Nationally Recognized Testing Laboratory (NRTL). That means electrical and fire-safety testing to applicable standards, which is the baseline that inspectors and facilities managers look for in the United States. For a beginner 3d printer, this is a practical signal that the machine is built with protective features for continuous operation.

The IECEE CB Scheme is a global program administered by the International Electrotechnical Commission that lets one IEC test report support national approvals in many markets. It helps manufacturers and buyers navigate cross-border compliance efficiently. It does not replace local listings, so it is still wise to check the exact mark used in your region before deployment in schools or offices.

What This Means for You

- Clear documentation for organizations that require proof of electrical and fire-safety testing.

- Added confidence to run multi-hour prints without constant supervision, though initial monitoring is always recommended.

- A simpler path to approvals if you plan to move the same unit between sites in different countries.

Which 3D Printer Is Safer for Home Use, Open Frame or Enclosed?

Entry-level, open-frame devices let emissions disperse into the room the moment they are generated. An enclosed design directs airflow, keeps warm air inside, and routes it through the filtration path. If your goal is a clean, quiet corner that still produces strong parts, an enclosed approach provides a clear advantage for indoor air quality.

At-a-Glance Comparison

| Aspect | Open Frame | Enclosed with Triple Filtration |

| Air pathway | Free convection into the room | Directed through pre-filter, HEPA and carbon |

| Odor control | Room absorbs smells | Carbon reduces common printing VOCs |

| Particle capture | None | H12 class media targets fine particulate per EN 1822 |

| Room impact during long jobs | Higher | Lower due to enclosure and filtration |

| Material range | Draft-sensitive plastics are harder to print | Active chamber heat supports ABS and PC with fewer issues |

A careful reader will notice something else. Enclosure also improves thermal stability around the part, which helps reduce warping. Cleaner air and better print consistency happen together because the same chamber control supports both.

Benefits for Home and Studio 3D Printing

The Q2's enclosure, filtration, and thermal control change the day-to-day experience in a small space. It is easier to focus on design and finishing when odors fade quickly, and the machine sounds like equipment that belongs in a living room or a classroom. A capable 3D printer should also make it simple to switch materials without turning the room into a workshop.

For Families and Shared Rooms

- Less noticeable odor after long prints, which keeps common areas comfortable.

- A chamber door that stays closed during jobs, with filtering that continues for a short cool-down period.

- A straightforward care routine that takes a few minutes each week.

Special Consideration: If pregnant women, young children, or individuals with asthma or chemical sensitivities are regularly present, additional room ventilation or placement in a dedicated workspace is strongly recommended regardless of filtration capability.

For Small Studios and Offices

- Fewer pauses to air out between iterations on a client project.

- More flexibility to run engineering filaments on busy days because the chamber holds temperature.

- A cleaner bench for sanding, drilling, or painting finished parts.

For Long Prints

- Plan for overnight jobs by checking the filter condition and room ventilation beforehand.

- Keep the chamber closed a bit after completion to let the filter finish its work.

- Review material safety data sheets (MSDS) for ABS and PC so you can choose temperatures that balance strength and emissions.

Set Up for Clean Air with Proper Placement, Venting, and Filter Care

A good setup reduces exposure before you even press print. Give the chassis a few inches of clearance on the back and sides to maintain smooth airflow. Place the unit in a room where you can open a window or run a small fan during long sessions. The Q2's chamber heater reaches 65°C, which is 149°F, so the surrounding area should stay uncluttered and dry. These small choices improve comfort and make maintenance easier for any 3D printer.

Placement That Helps the Filter Work

- Keep the rear exhaust area unobstructed so the fan does not work harder than it should.

- Avoid corners with dead air that trap warm air and smells.

- Use a level, vibration-resistant surface to keep the enclosure sealed during travel moves.

Venting Options for Sensitive Users

- Establish a light airflow toward a window during multi-hour jobs if you are sensitive to smell.

- If your space allows, route the rear exhaust outdoors with an appropriate duct kit (consult ASHRAE guidelines for residential ventilation rates if designing a permanent installation).

- Close the chamber door while the print cools so treated air stays in the loop longer.

Filter Care That Fits a Busy Week

- Inspect the pre-filter weekly and vacuum gently if lint builds up.

- Track hours printed on ABS and PC and shorten carbon replacement intervals when those materials dominate. As a guideline, consider replacement every 200-300 hours for ABS/PC use, or 400-500 hours for PLA/PETG.

- Keep a spare filter on hand so you can swap quickly and stay on schedule.

Why QIDI Q2 Offers Enhanced Safety for Home 3D Printing

You want reliable parts and clean air without complex workarounds. The Q2 combines a sealed chamber, a G3 plus H12 plus activated carbon filter, and safety marks that carry weight in the United States and internationally. It also offers an active chamber heater that supports engineering filaments while the filtration system treats the internal airstream. For a beginner 3D printer, those choices simplify life. You set it up once, follow a simple maintenance routine, and enjoy home printing with fewer tradeoffs.

Among enclosed printers in its class, the Q2 stands out for combining certified electrical safety (MET/IECEE CB), comprehensive filtration meeting EN standards, and active thermal management in a package designed for home and educational use.

5 FAQs About 3D Printer Health and Safety

Q1: Where Should I Place the Printer in a Central HVAC House?

Keep the printer away from the return vents for the HVAC system to prevent emissions from circulating through ductwork. Use a room with exhaust capability or window ventilation, or keep the door to the room closed with clearance of a few inches at the back and sides of the unit for proper airflow.

Q2: Can a Room Air Purifier Help, and How Do I Choose the Right Size?

Yes, a room air purifier can complement built-in filtration for longer prints. For a typical 150 sq ft room with 8 ft ceilings (approximately 1,200 cubic feet), choose a unit rated for at least 100 CFM CADR to achieve 4-5 air changes per hour when working alongside the Q2's built-in filtration. This recommendation aligns with EPA guidance for indoor air quality improvement in spaces with occasional pollutant sources.

Q3: How Will I Know When to Change the 3-in-1 Filter?

Take a baseline airflow reading through the exhaust using a pocket anemometer when the filter is new. When readings show a persistent drop of 20-30%, print results in odor returning faster, or fan noise increases noticeably at normal print speeds, replace the filter. Track cumulative hours by material type: ABS or frequent PC usage may require replacement at 200-300 hours, while PLA/PETG can extend to 400-500 hours depending on print volume.

Q4: What Are the Best Materials for Indoor Printing of Functional Parts?

PLA has a light, sweet smell and minimal emissions, but softens at lower temperatures (around 60°C), limiting functional use.

PETG offers good strength and impact resistance with lower emissions than ABS, making it suitable for indoor use with basic ventilation.

ASA performs like ABS outdoors with better UV resistance but may emit styrene; ensure adequate ventilation or use exhaust ducting.

Nylon (PA) provides excellent mechanical properties but releases caprolactam during printing. Use enhanced ventilation or direct exhaust ducting for nylon work, and consult material safety data sheets.

Always reference the material's MSDS for specific VOC information and recommended handling.

Q5: What Documentation Do Schools or Offices Need for Compliance?

For institutional deployment, maintain the following documentation:

- Material Safety Data Sheets (MSDS) for all filaments in use

- Equipment safety certificates (MET, IECEE CB, or equivalent for your region)

- Standard Operating Procedures (SOP) covering enclosure operation, ventilation requirements, and filter maintenance schedules

- Maintenance log with dates, operating hours, and filter replacement records

- Basic risk assessment addressing ventilation, material handling, and emergency procedures

- Staff training records documenting safety briefings for inspection readiness

Consult your facility's environmental health and safety (EHS) department or local regulatory authority for specific requirements in educational or commercial settings.

Disclaimer: While this guide provides general safety recommendations for 3D printing, it does not replace professional assessment of your specific environment, local building codes, or occupational safety requirements. Users are responsible for ensuring compliance with applicable regulations and for monitoring their own workspace conditions.

Q2

Q2

QIDI Box

QIDI Box

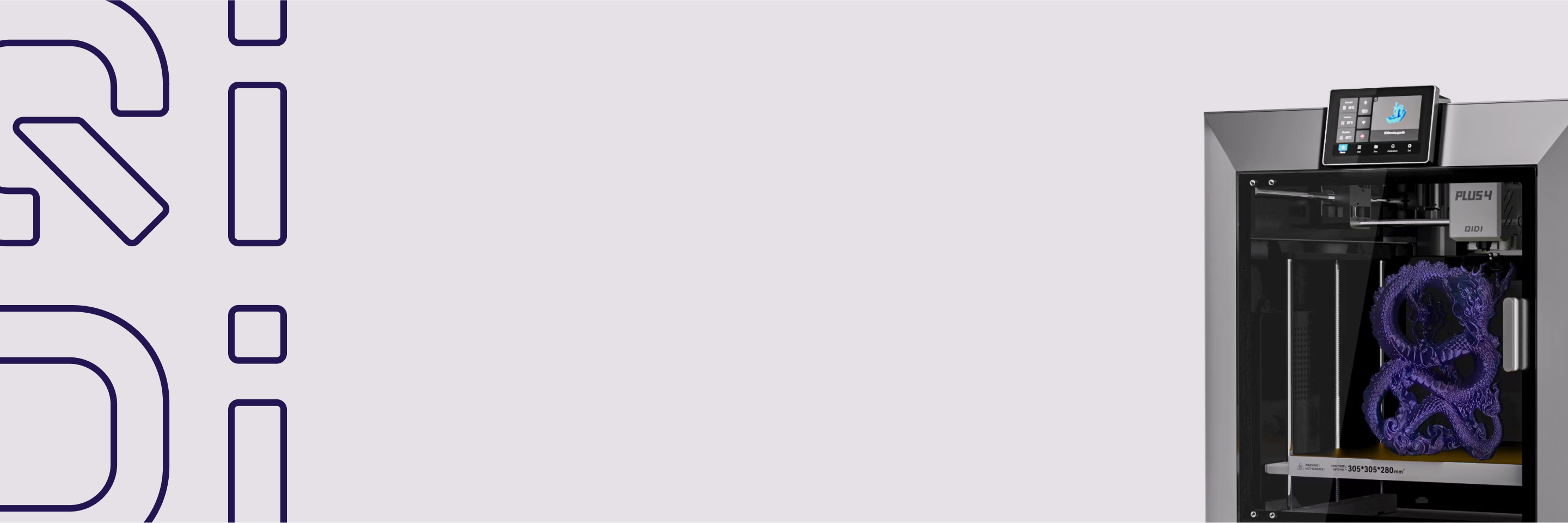

Plus 4

Plus 4

Q1 Pro

Q1 Pro

X-Max 3

X-Max 3