From First Layer to Final Prototype: How to Find the Perfect 3D Printer for Your Projects

There is a unique kind of magic in watching a digital file on your screen slowly materialize into a solid object you can hold in your hand. This is the promise of 3D printing, a technology that has moved from high-tech labs into homes, workshops, and offices around the world. The possibilities feel endless. Yet, taking that first step can feel overwhelming. You are faced with a market flooded with models and a dictionary of technical terms like FDM, CoreXY, and SLA.

This confusion often leads to hesitation, preventing talented people from exploring what this amazing technology can do for them. This guide is designed to clear away that fog. We will provide a straightforward, project-based framework to help you choose the perfect 3D printer. The goal is to help you understand the technology so you can confidently select a machine that matches your specific needs, whether you are a hobbyist, a designer, or an engineer.

What is 3D Printing and Why is an FDM 3D Printer a Great Start?

At its core, 3D printing is a process of building objects layer by layer from a digital design. This method is also known as additive manufacturing because it adds material to create an object, unlike traditional methods that subtract material by cutting or drilling. While there are several types of 3D printing technology, the most common and accessible for newcomers is Fused Deposition Modeling, or FDM.

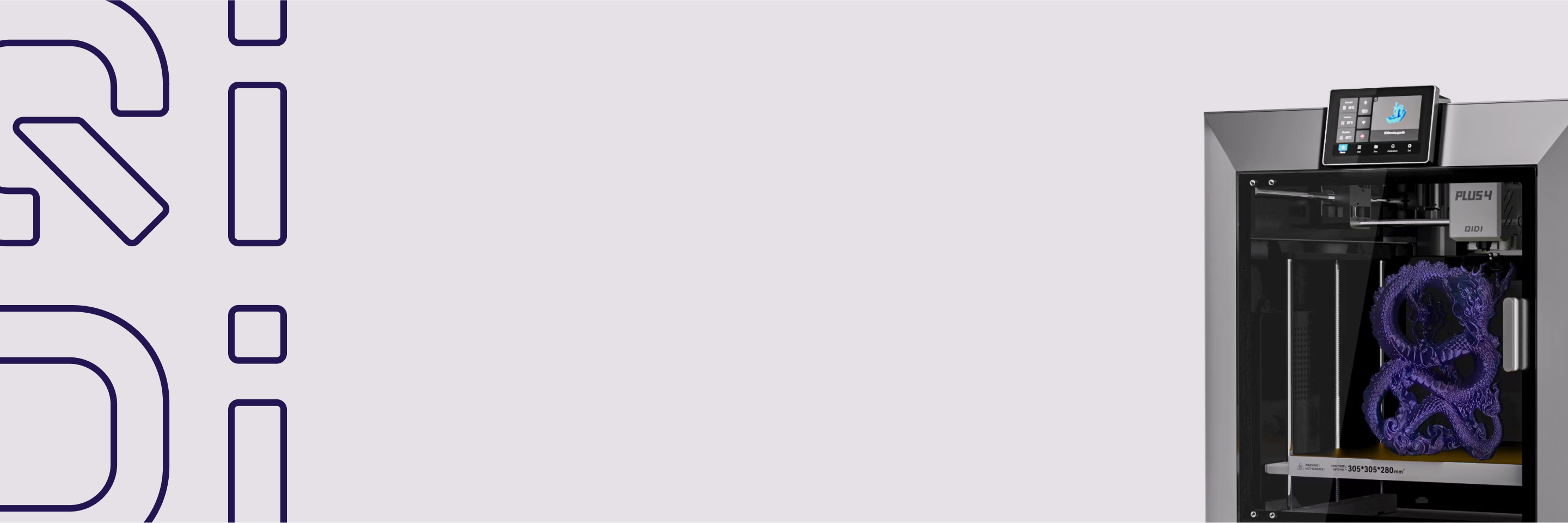

Think of an FDM 3D printer as a highly precise, computer-controlled hot-glue gun. It melts a plastic filament, extrudes it through a tiny nozzle, and deposits it layer by painstaking layer to build your model. For most people starting their journey in 3D printing, FDM is the ideal choice. The printers are affordable, the parts they produce are durable, and the variety of available printing materials is vast. This combination makes an FDM 3D printer a versatile and cost-effective foundation for almost any project you can imagine.

Which Type of 3D Printer is Right for My Project-Based 3D Printing?

The most important question is not "what is the best 3D printer?" but rather "what is the best 3D printer for me?". The answer depends entirely on the kinds of projects you plan to tackle. Let's break down the common user types and the features they should look for.

For the Hobbyist & Creative Beginner

If you are just starting, your projects likely involve learning the ropes and having some fun. You might be printing small toys, figures for a tabletop game, useful household gadgets, or custom phone stands. Your focus is on creativity and exploration.

What you need in a 3D printer:

- Ease of Use: The machine should work well right out of the box with minimal complex setup.

- Reliability: You want to spend your time printing, not troubleshooting.

- Safety and Simplicity: Features that make the process smoother and safer are a priority.

For these goals, look for an entry-level, user-friendly printer. The key feature to demand is reliable automatic bed leveling, which handles one of the most frustrating parts of the setup process for you. A simple touchscreen interface and a modest build volume that fits on a desk are also ideal. Some printers in this category even come with an enclosure, which is a fantastic bonus for improving print consistency and providing an extra layer of safety.

For the Advanced Maker & Product Designer

Your projects have grown in scale and complexity. You are now creating functional prototypes to test form and fit, larger decorative pieces that make a statement, or custom enclosures for your electronics projects. You need parts that are not just visually appealing, but also strong and potentially heat-resistant.

What you need in a 3D printer:

- Material Versatility: The ability to print with engineering-grade filaments like ABS, ASA, or PETG.

- Larger Build Volume: Your ideas need more space to come to life.

- High Precision: Your functional parts require tight tolerances.

You should be looking for a versatile, mid-size "prosumer" 3D printer. The single most important feature in this category is an actively heated build chamber. This is not just a nice-to-have; it is essential for successfully printing high-temperature materials like ABS without the risk of warping or layer splitting. A heated chamber keeps the ambient temperature around the model consistent, ensuring strong, stable parts. You should also prioritize a robust, all-metal frame and high-precision components for reliable, accurate results.

For the Engineer & Small Business Owner

You are pushing the boundaries of the technology. Your work may involve creating large-scale, functional models, producing end-use parts for sale, or manufacturing jigs and fixtures to improve your workshop's workflow. Time is money, and performance is paramount.

What you need in a 3D printer:

- Maximum Build Volume: Your projects are large, or you need to produce multiple parts at once.

- Speed and Efficiency: You need to iterate quickly and meet production demands.

- Consistent Performance: The printer must be a reliable workhorse capable of running for many hours or even days at a time.

Your search should focus on a large-format 3D printer. Here, the main priority is getting the largest build volume you can find. However, do not let size come at the expense of professional features. Ensure the machine still includes the essentials from the prosumer class, like a heated chamber and rock-solid construction. High-speed performance, often enabled by a CoreXY motion system, is also critical to ensure your large prints are completed in a reasonable timeframe.

What Key Features Should I Look For in a Modern 3D Printer?

As you compare models, you will encounter a lot of technical terms. Here is a simple guide to what the most important ones mean for your 3D printing experience.

- CoreXY Kinematics: This is an advanced motion system for the print head. Instead of a single motor for each axis, it uses a clever belt arrangement. For you, this means the printer can move faster and with greater precision, leading to cleaner prints that finish in a fraction of the time.

- Heated Chamber: This is an enclosed build area that is actively heated. Its purpose is to maintain a stable, warm environment around the print. This is the key to working with strong, engineering-grade materials like ABS, as it prevents the plastic from cooling too quickly and warping.

- Automatic Bed Leveling: This is a must-have convenience feature. A sensor on the print head measures points across the build surface, and the printer's software automatically compensates for any slight imperfections. It nearly guarantees a perfect first layer, which is the foundation of every successful print.

- Direct Drive Extruder: This refers to the mechanism that pushes filament into the hot end. A direct drive system places the motor directly on the print head. This provides excellent control over the filament, which is especially useful for printing flexible materials and for achieving high-quality results at fast speeds.

How Much Work is a 3D Printer to Maintain for Quality 3D Printing?

It is true that early consumer 3D printers often required the patience of a saint and the skills of a mechanic. Thankfully, the industry has matured significantly. Modern machines are designed for reliability and require far less tinkering. The most important maintenance tasks are simple and straightforward.

You will need to keep the build plate clean to ensure your prints adhere properly. You should also periodically check that the nozzle is clear of any debris and that the belts are appropriately tensioned. Beyond these simple checks, most of the upkeep involves following the manufacturer's guidance for lubricating the moving parts. Think of it as simple upkeep for a valuable tool, not a complex engineering challenge. A good 3D printer should empower your creativity, not become a project in itself.

How Can You Start Your 3D Printing Journey Today?

Choosing the right 3D printer is a journey of matching the machine to your mission. It is not about finding a single "best" model, but about understanding your own goals and identifying the features that will help you achieve them. By now, you should have a clear idea of the path forward.

You can begin with a reliable, user-friendly machine to master the fundamentals of 3D printing. As your skills grow and your ambitions expand, you can advance to a prosumer model with a heated chamber to unlock the world of advanced materials. When your ideas become truly grand, you can scale up to a large-format printer capable of bringing them to life.

Your next great idea is waiting to be built. Armed with this knowledge, you can now confidently navigate the market, cut through the noise, and choose the perfect tool to begin your 3D printing adventure. Happy printing!